Work Access Platform

Work Access Platform

Couldn't load pickup availability

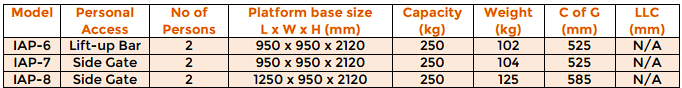

Our range of Access Platforms provide a safe environment for a wide range of maintenance and inspections to be carried out from, with the reassurance that they have been manufactured in accordance with HSE document PM28 4th Edition.

Standard Features

• Automatic locking and unlocking gates (IAP-7 & 8 only)

• Hinge back guard for ease of transportation and storage

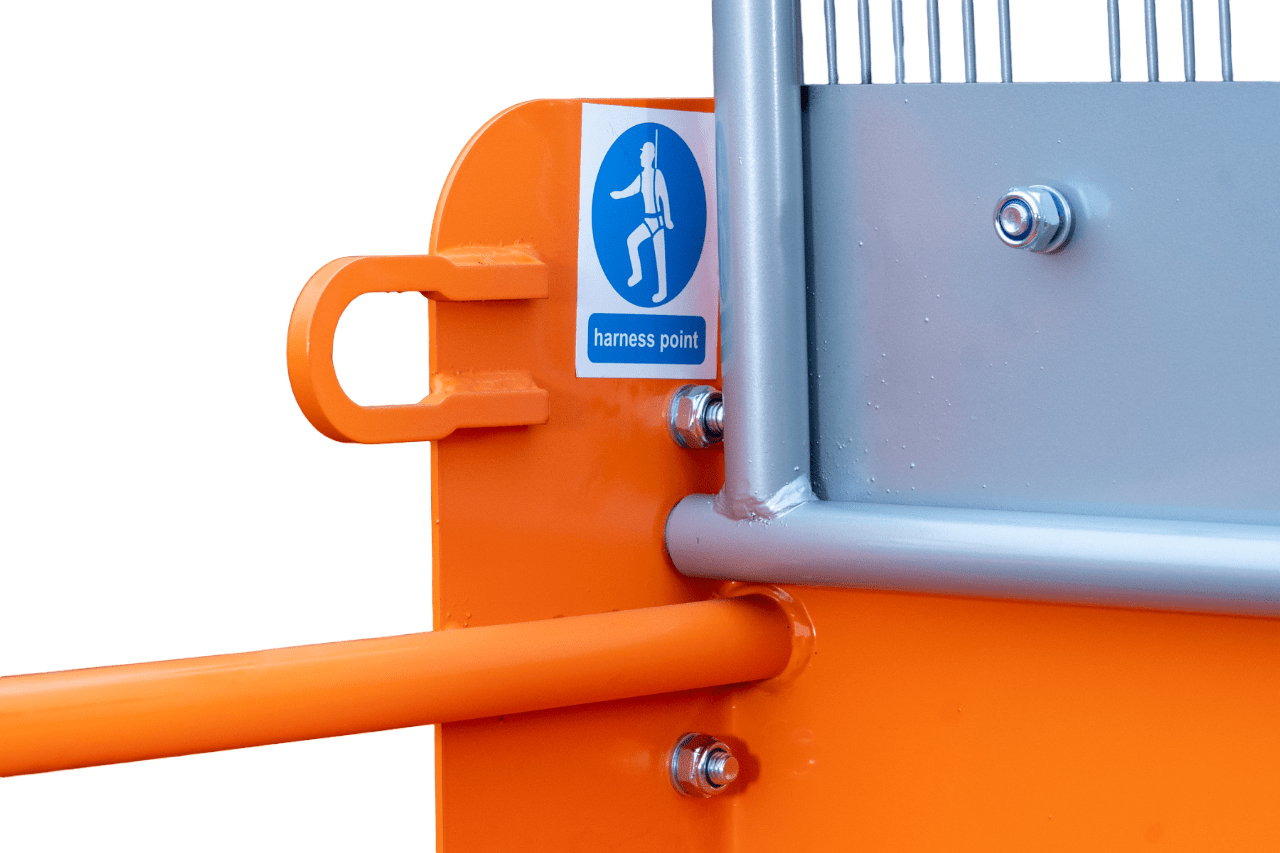

• Safety harness attachment rings

• Self-draining non-slip floor

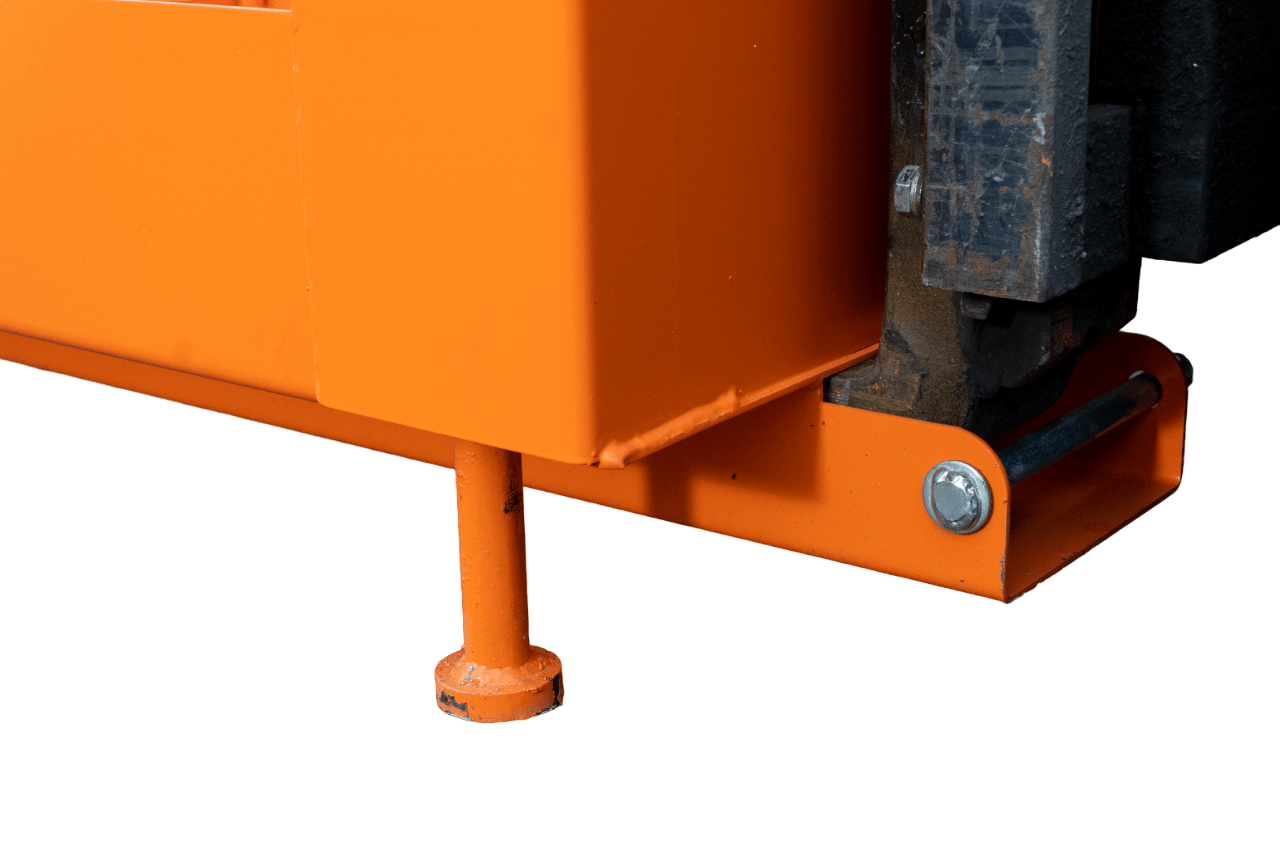

• Zinc plated heel pins for safe attachment to truck

• Maximum fork section 150 x 50 mm at 525 centres

• Painted bright orange for safety

Share

Collapsible content

Collapsible content

Operation

On Receipt of the Access Platform:

We would recommend that two people carry out the assembly of the unit, beginning with the removal of all packaging. Following this, lift the back guard of the unit into an upright position and fix the 4 (M12) Bolts supplied into the four slotted holes. Fully tighten the bolts. This now ensures that the Access Platform is ready for use.

Operation

- The product must be positioned on level ground.

- Position the forks to the correct distance apart to locate into fork pockets.

- Remove fork pocket heel pins from access platform and drive forks into fork pockets.

- Insert fork pocket heel pins directly behind the heel of fork and attach safety lynch pin into hole provided.

- Models with gates automatically lock once raised and unlock when placed on level ground.

- The attachment is now ready for use.

Maintenance

- The access platform should be inspected weekly for general condition with particular attention paid to:

A – All weld points

B – Wear & distortion of fork pockets and heel pin attachments.

C – Any damaged components

D – Lock & latches

- General surface rusting especially in critical areas should be treated with proprietary inhibitors, primers and paint on a regular basis.

- All hinges, latches and locks must be kept lightly greased.

- Damage or failure must be reported or rectified immediately prior to re-use of access platforms.

- This product is certified for six (6) months from the date of manufacture after which it is the customer’s responsibility to have the product re-tested at an approved testing facility or inspected and logged in a register by a competent

person as advised by the HSE.

Health And Safety

- The manager of the department or section where the attachment is to be used must be responsible for ensuring the operators are fully conversant with the attachment, its operation, maintenance and that the heel pins are fitted correctly.

- The fork truck handbrake must be applied when elevating and lowering the access platform and when in use always.

- Ensure that mast is kept in the vertical position.

- Ensure that the Heel Pins are correctly inserted, retained and positioned in relation to the heel of the fork prior to each use and every use.

- Always make sure the access platforms maximum load is not exceeded.

- The fork truck driver must remain seated and in control always whilst the access platform is in use.

- The driver must ensure a slow, uniform pace is maintained, at ground level, whilst moving and positioning the access platforms and keep clear of obstructions.

- It is recommended that a safety harness is used always and personnel attach themselves to the Platform via the harness loop provided.

- The access platform must not be re-positioned whilst in the elevated position.

- Keep hands and fingers clear of all moving parts to prevent trapping.

- Operation and use of this product is covered by the H.S.E. guidance note PM28 fourth edition “Working Platforms on Forklift Trucks”.

- Operation and use of variable reach truck (telehandler) is covered by publications from the Health and Safety Executive.