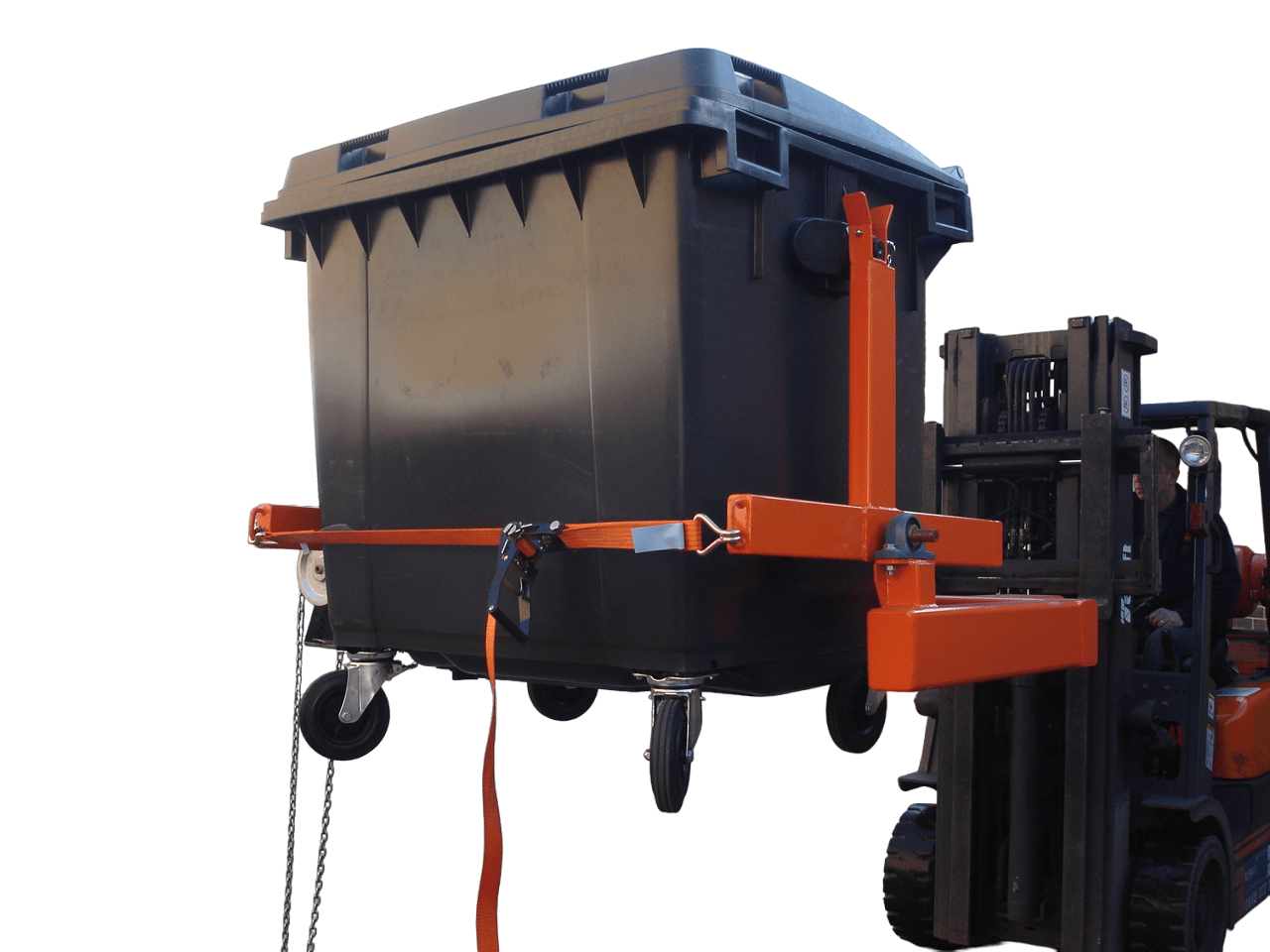

Wheelie Bin Lifter / Tipper

Wheelie Bin Lifter / Tipper

Couldn't load pickup availability

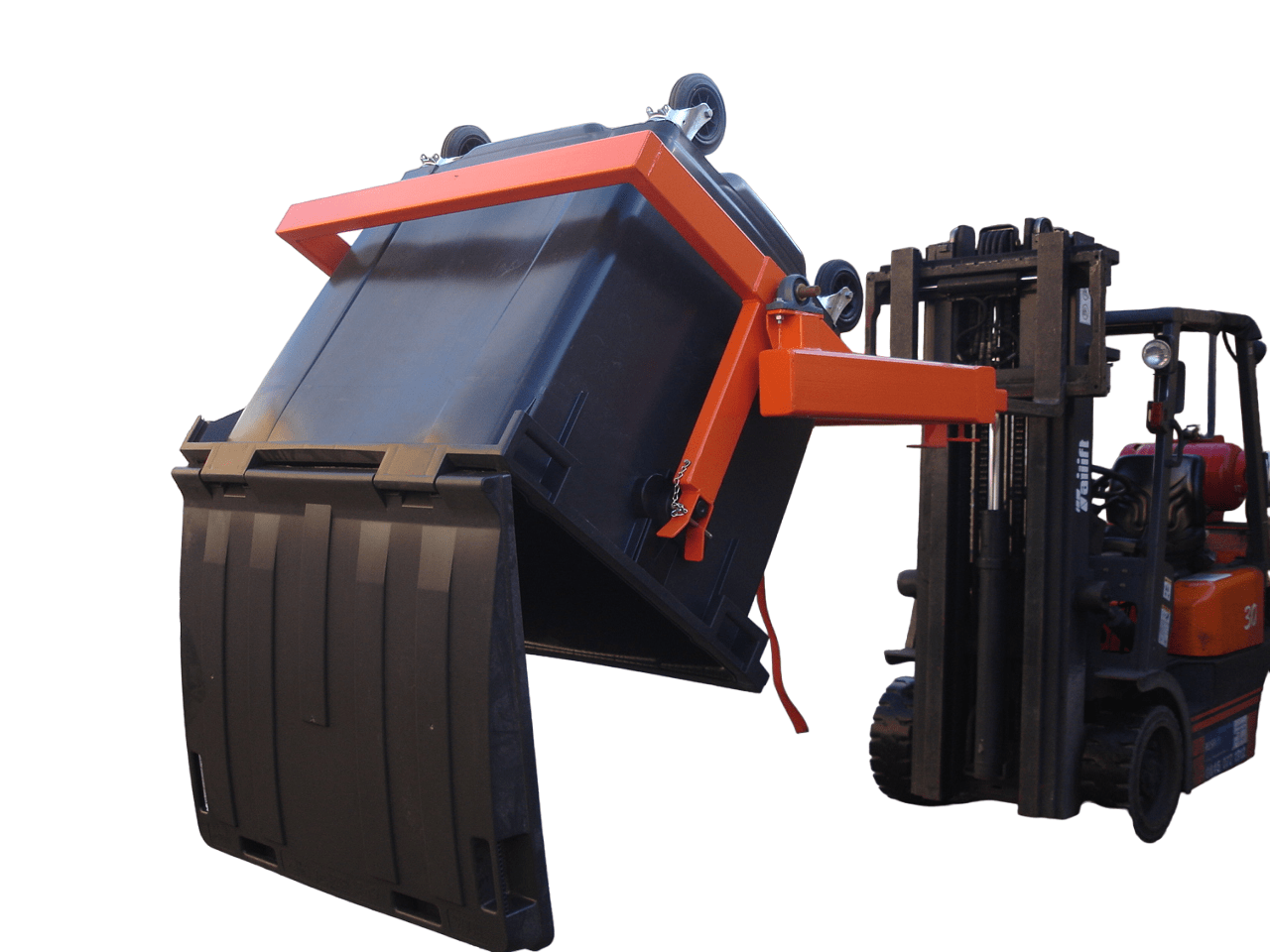

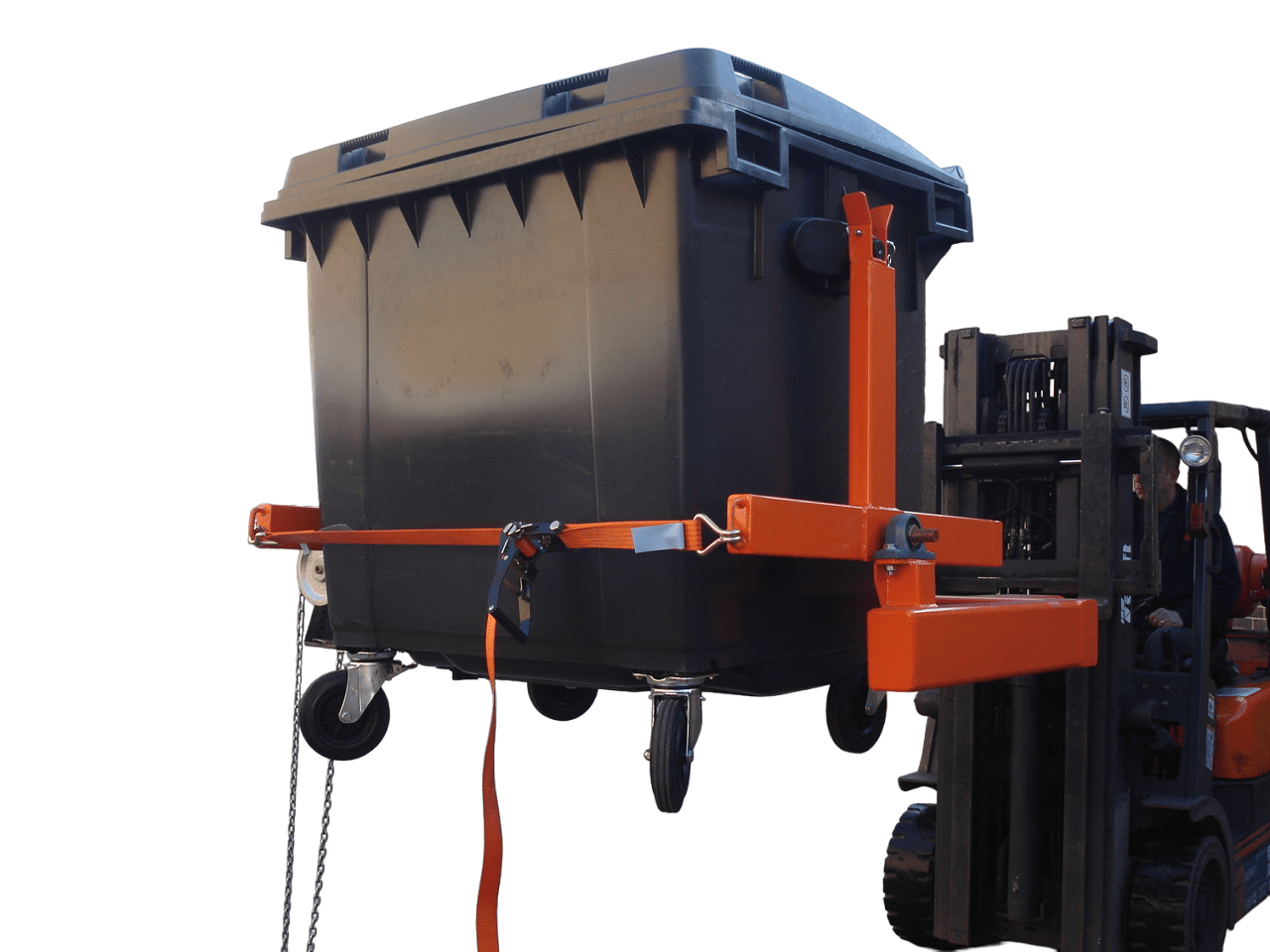

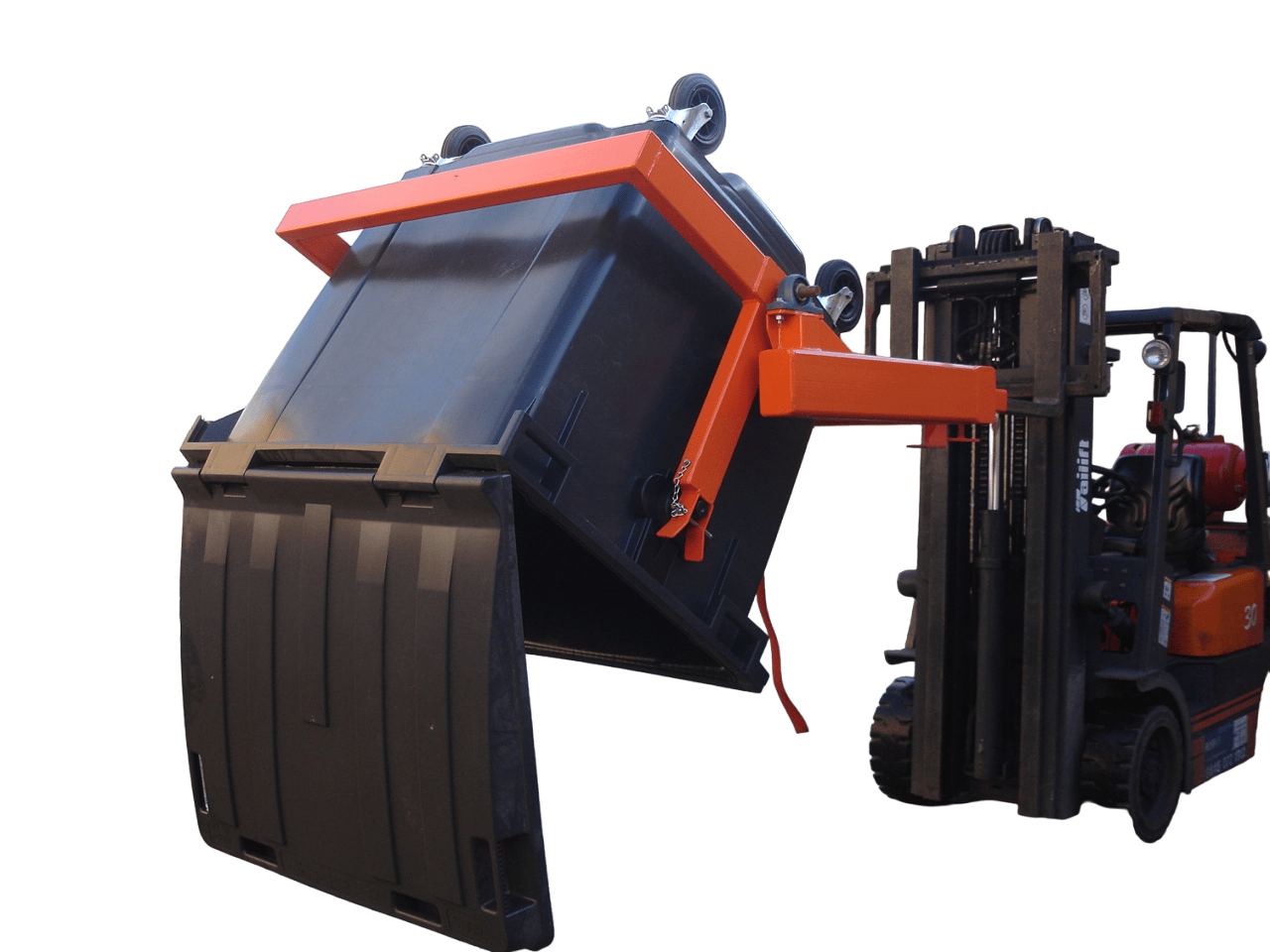

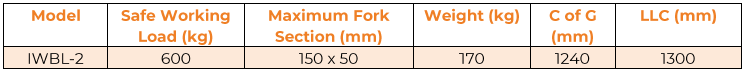

The Fork Mounted Wheelie Bin Lifter / Tipper is designed to safely lift, move and empty 660 and 1100 litre wheelie bins equipped with side trunnions. With this type of waste management becoming more and more popular by the day, it is this attachment which can offer a solution to the associated logistical and time-keeping constraints. The attachment is operated via a gearbox and endless chain for safe use from low level.

Standard Features

• 50-1 geared gearbox

• 6 metres endless chain

• Ratchet tensioner strap to leading edge

• Zinc plated twist screws for safe attachment to a truck

• Painted bright orange for safety

Share

Collapsible content

Collapsible content

Operation

1. Position the forks at the correct distance apart to locate into the fork pockets and drive fully into the pockets.

2. Tighten thumbscrew retention on both forks.

3. Remove sprung loaded pins at the top of the trunnion arms in preparation for picking up wheelie bin and undo ratchet strap across the front of the attachment. Ensure the strap does not get caught under the forklift truck.

4. Lift the attachment clear of the floor and with the body of the attachment horizontal to the ground, approach the rear of the bin, positioning the trunnion arms under the trunnions of the bin.

5. Lift the attachment to engage the trunnions and replace the sprung loaded pins to hold the trunnions in place.

6. The ratchet strap is then fastened at the front of the bin to hold it securely into the frame of the attachment.

7. The whole unit can now be moved to the discharge area and the handbrake applied, ready for lifting.

8. Before lifting, remove the loop chain from the storage box.

9. Once lifted into the correct emptying position and height, operate the gearbox by means of the continuous loop chain and rotate the bin forwards to empty the contents.

10. The gear box can be left at any angle during the unloading process and will hold in place at any angle when left unattended.

11. Once discharged, rotate the bin back to horizontal, lower to the floor and replace the loop chain into the storage box for travelling.

12. The ratchet strap is then released, trunnion pins removed and the attachment reversed away from the bin.

13. You are now ready for your next lift.

Maintenance

1. The Wheelie Bin Lifter should be inspected weekly for general condition with particular attention paid to:

A – All weld points.

B – Wear and distortion of fork pockets and heel pin attachments.

C – Any damaged/worn components.

D – General condition of cable, pulley and winch.

2. Damage or failure must be reported and rectified immediately prior to re-use of the attachment.

3. General surface rusting especially in the critical areas should be treated with proprietary inhibitors, primers and paint on a regular basis.

4. This product is certified for six (6) months from the date of manufacture after which it is the customer’s responsibility to have the product re-tested at an approved testing facility or inspected and logged in a register by a competent person as advised by the HSE.

Health And Safety

1. The manager of the department or section where the attachment is to be used must be responsible for ensuring the operators are fully conversant with the attachment, its operation, maintenance and that the heel pins are fitted correctly.

2. Ensure both the truck and attachments are capable of handling the intended load and its contents.

3. Ensure the thumbscrews are correctly utilised.

4. Do not drive into the fork pockets without unscrewing the thumbscrews from the pockets.

5. Do not shock load the attachment under any circumstances.

6. Do not drive the forklift with the wheelie bin in a dangerously high position.

The Operator should ensure that the above product is used for the purpose that it has been designed, tested and intended to do and no deviation to this occurs. If in doubt, consult your Fork Truck Dealer or approved Attachment Supplier.