1

/

of

4

Fork Mounted Magnet

Fork Mounted Magnet

Regular price

£630.00

Regular price

Sale price

£630.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

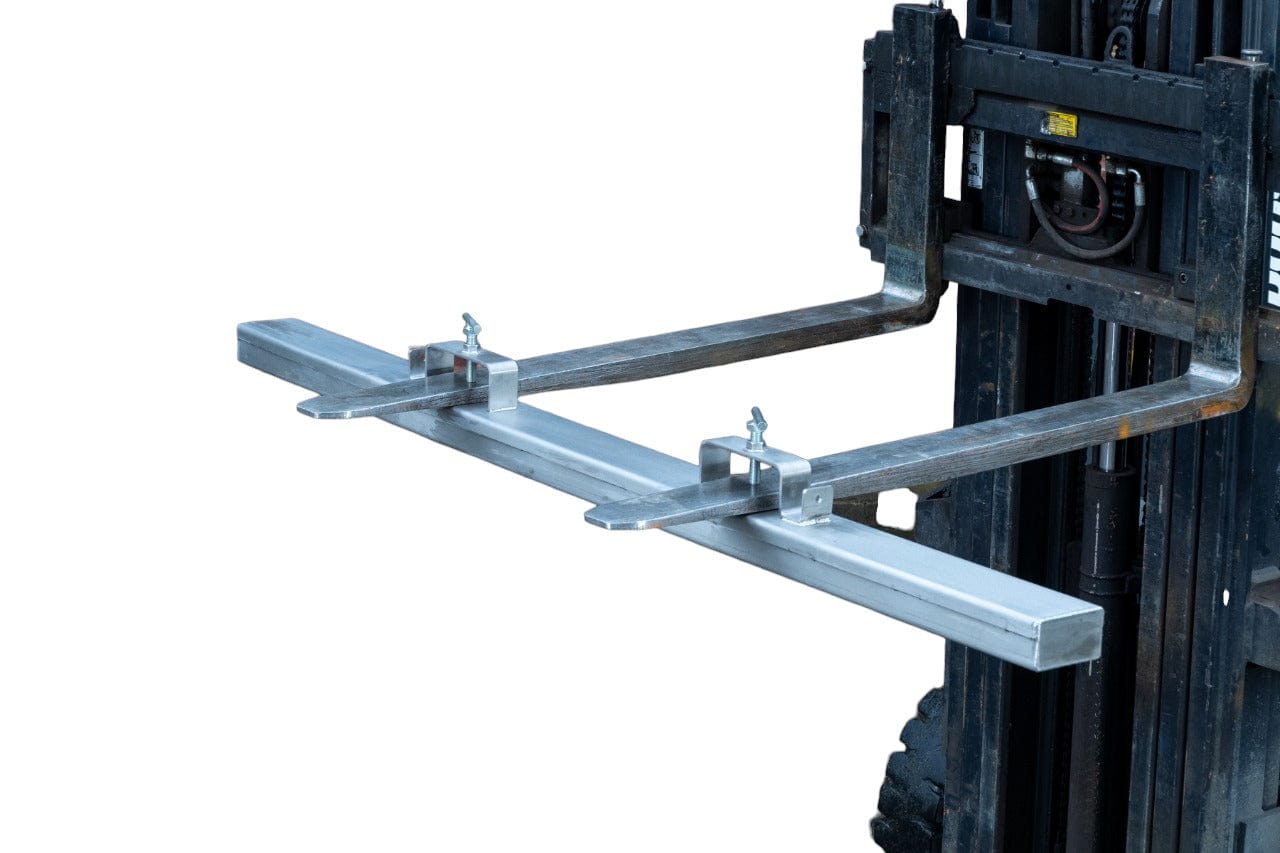

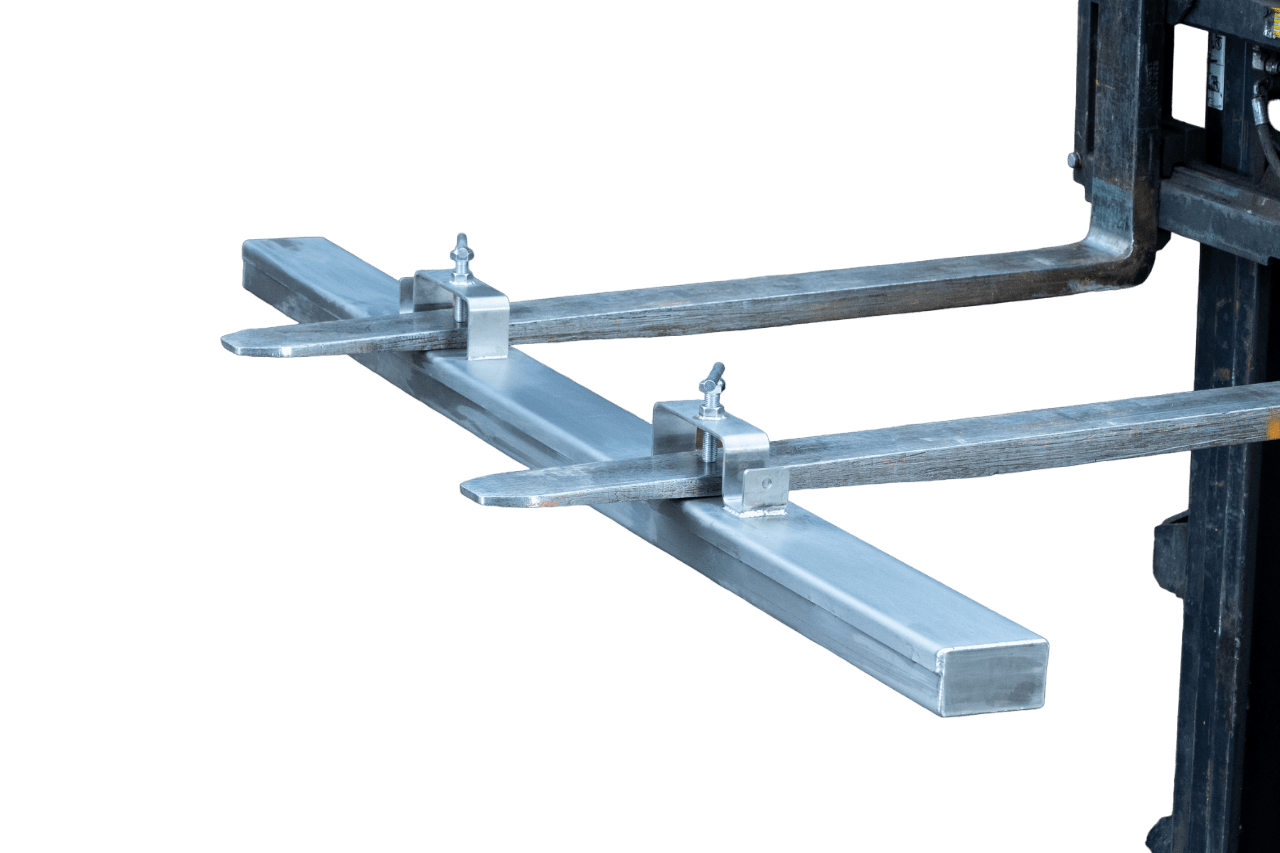

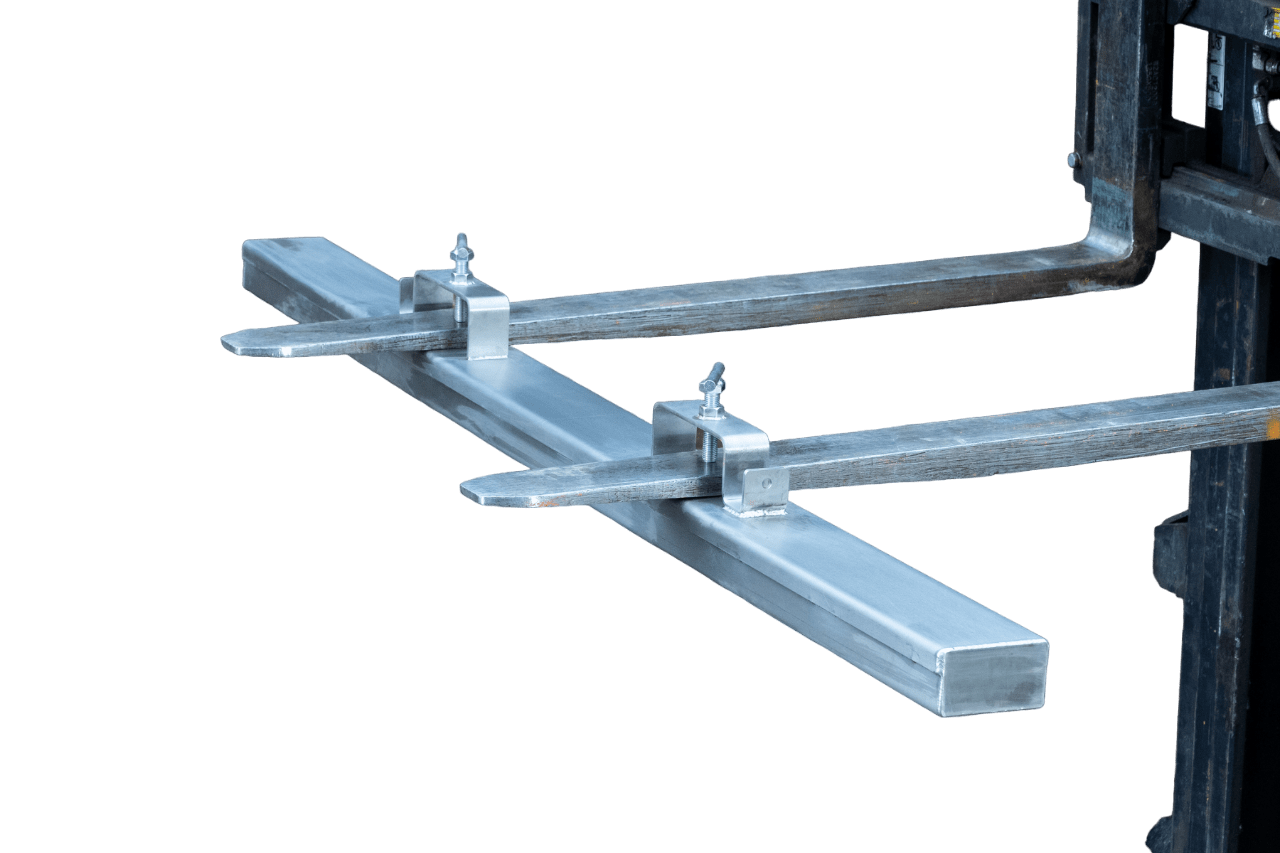

The Fork Mounted Magnet is a simple but effective method of clearing factory floors, car parks and goods yards of unwanted steel debris that could otherwise present a hazard to pneumatic tyres and operatives alike.

Standard Features

• Facility to hang from the Fork Mounted Sweeper

• Polished stainless-steel finish

• Maximum fork section 150 x 60 mm at 683mm centres

• Zinc plated twist screws for safe attachment to truck

Share

Collapsible content

Collapsible content

Operation

- Position forks to desired distance apart.

- Drive forks into the fork pockets above the magnet.

- Tighten the thumbscrew retention on to the forks ensuring they are adequately tightened.

- The attachment is now ready for use.

- Position the magnet 75/100mm from level floor and drive at the appropriate speed to suit the type of waste and terrain for effective collection.

- When finished, raise the magnet to a workable height and scrape the magnet to remove collected product from the base into a receptacle.

Maintenance

- The magnet should be inspected weekly for general condition with particular attention paid to: A – All weld points, B – Wear and distortion of thumbscrew attachments

- Damage or failure must be reported and rectified immediately prior to re-use.

- This product is certified for six (6) months from the date of manufacture after which it is the customer’s responsibility to have the product re-tested at an approved testing facility or inspected and logged in a register by a competent person as advised by the HSE.

Health And Safety

- The manager of the department or section where the attachment is to be used must be responsible for ensuring the operators are fully conversant with the attachment, its operation, maintenance and that the thumbscrews are fitted correctly.

- Ensure both the truck and attachments are capable of handling the intended load and its contents.

- Ensure the shackle pin is adequately tightened before each use.

- Ensure the thumb screws are not tightened onto taper of blade.

- On removal of the magnets collections, please be aware of sharp steel and remove risk by wearing safety gloves.