1

/

of

5

Height Adjustable Extending Jib

Height Adjustable Extending Jib

Regular price

£1,751.52

Regular price

Sale price

£1,751.52

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

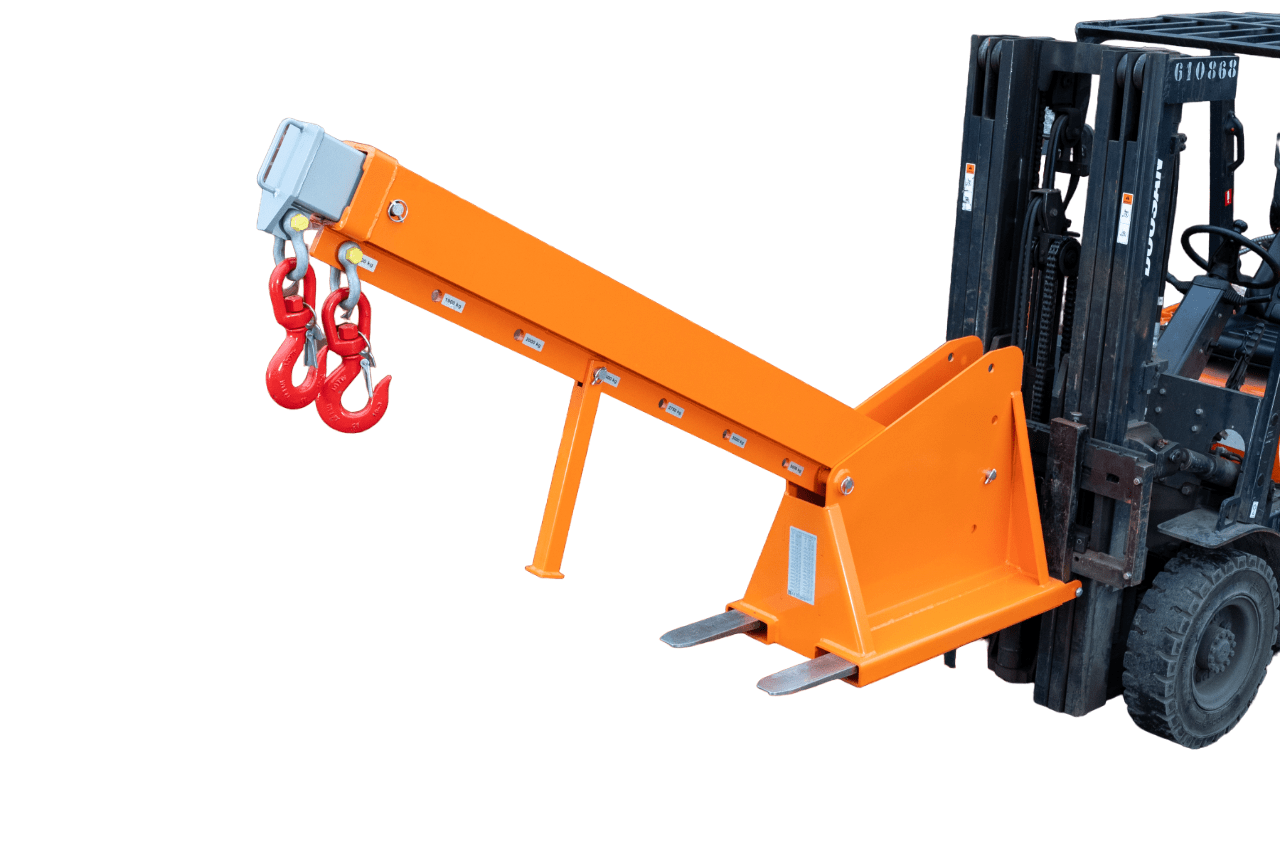

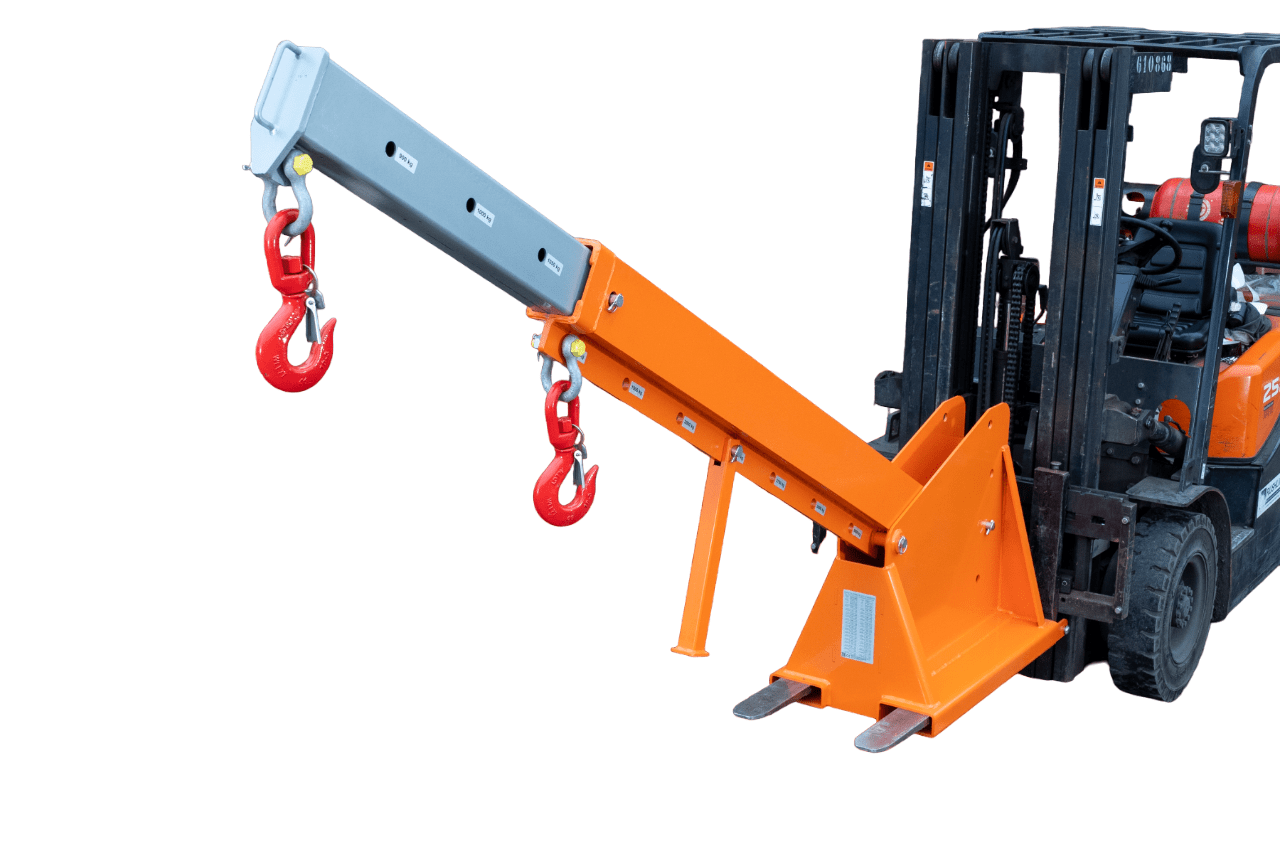

The Height Adjustable Extending Jib has all the characteristics of the standard incline fixed jib with the additional benefit of angular lifts. This allows tall and awkward loads to be lifted by increasing the lift height of the forklift truck or tele handler.

Standard Features

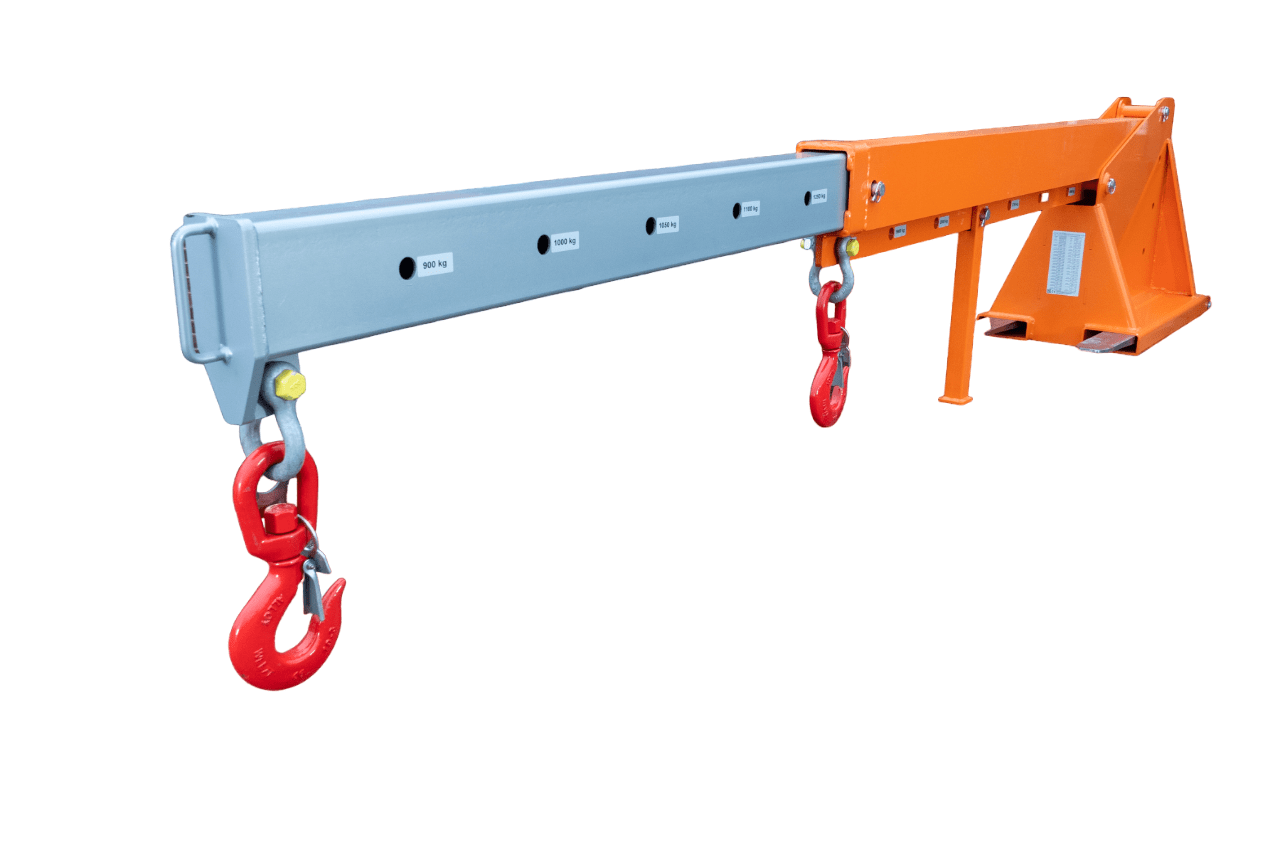

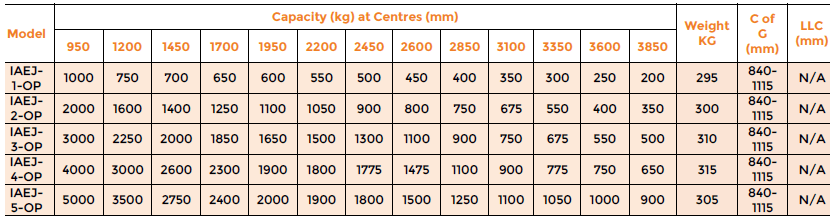

• Multi hook positioning from 950-3850mm load centres.

• Adjustable angled lift at 0°, 15°, 30° and 45°.

• Supplied complete with 2 No swivel hooks.

• Maximum fork section 150x50mm at 350mm centres.

• Zinc plated heel pin for safe attachment to truck.

• Painted bright orange for safety.

Share

Collapsible content

Collapsible content

Operation

- Position the forks to the correct distance apart to locate into fork pockets.

- Remove the heel pin(s) from the attachment.

- Drive the forks into the fork pockets.

- Insert fork pocket heel pin(s) directly behind the heel of the fork and attach safety lynch pin into hole provided.

- Position each swivel hook and shackle to the desired lifting point, ensuring that each shackle is adequately tightened.

- To extend or retract the extending boom remove the beam locating pin and pull/push on the handle located on the end of the boom until the hole in the extending boom aligns with the hole in the fixed beam and replace the beam locating pin.

- The attachment is now ready for use. Remove the Height Angular Pin and Lynch Pin.

- Lift at the end of the extension beam until the hole in the beam and the fixed frame align then replace the height angular pin and lynch pin to retain the desired lift angle.

- The attachment is now ready for use

Maintenance

- The Height Adjustable Fork Mounted Extending Jib should be inspected weekly for general condition with particular attention paid to: A – All weld points, B – Wear and distortion of fork pockets and heel pin attachments, C – Any damaged/worn components, D – General condition of swivel hook, safety latch and shackle, E – Alignment and condition of extending boom.

- Damage or failure must be reported and rectified immediately prior to re-use of the attachment.

- General surface rusting especially in the critical areas should be treated with proprietary inhibitors, primers and paint on a regular basis.

- This product is certified for six (6) months from the date of manufacture after which it is the customer’s responsibility to have the product re-tested at an approved testing facility or inspected and logged in a register by a competent person as advised by the HSE.

Health And Safety

- The manager of the department or section where the attachment is to be used must be responsible for ensuring the operators are fully conversant with the attachment, its operation, maintenance and that the heel pins are fitted correctly.

- Ensure both the truck and attachments are capable of handling the intended load and its contents.

- Ensure the shackle pins are adequately tightened before each use.

- Ensure that the heel pin(s) are correctly inserted, retained and positioned in relation to the heel of the fork prior to each and every use.

- Do not drive into the fork pockets without removing the heel pins.

- Do not shock load the attachment under any circumstances.

- The Forklift Mast must be vertical at all times.

- The safe working load must not be exceeded at each lifting point.