1

/

of

4

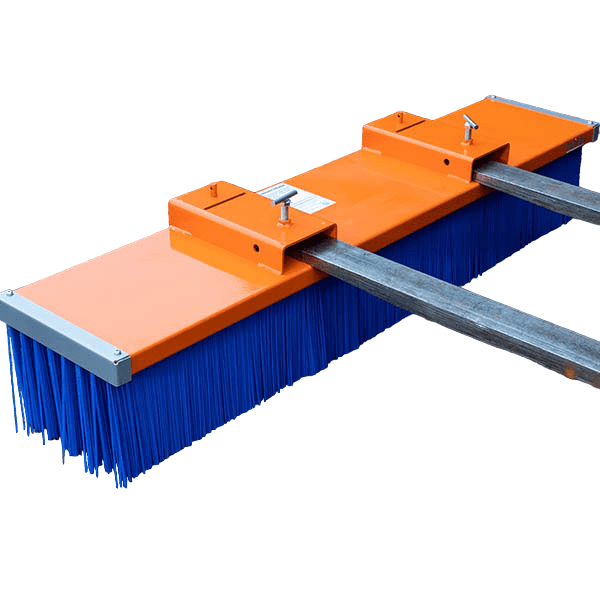

8 Row Sweeper

8 Row Sweeper

Regular price

£817.50

Regular price

Sale price

£817.50

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

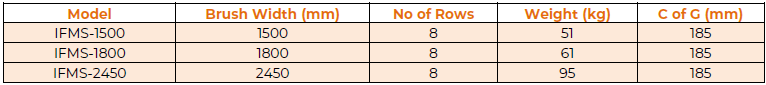

The Fork Mounted 8 Row Sweeper is a quick and easy solution for re-heaping your loose granule products such as sand, top soil, grain or similar. Available in 3 width combinations.

Heavy Duty Tasks

The 8 row sweeper is best suited where there are large open spaces and / or heavier masses to sweep.

Standard Features

• Interchangeable blue nylon brushes

• Facility to hang Fork Mounted Magnet from the frame

• Maximum fork section 150 x 60 mm at 683 mm centres

• Zinc plated twist screws for safe attachment to truck

• Painted bright orange for safety

Share

Collapsible content

Collapsible content

Operation

- Position the forks to the correct distance apart to locate into fork hoops.

- Drive forks into fork hoops until the tip of the forks touches the stop plate, firstly ensuring that the twist screws are suitably retracted.

- Once the forks are fully inserted tighten the twist screws onto the fork blade ensuring that they are fully tightened.

- The attachment is now ready for use.

- Lower the Brush so that the bristles are in contact with the sweeping surface and drive at a slow jogging pace and in a straight line. Distance will depend on sweeping surface and type of debris being swept.

- Once the desired distance has been reached, lift the brush clear of the sweeping surface and reverse to cover the same straight line run again (this is optional to the user dependent on surface, debris and desired result).

- Continue point 5 & 6 until area has been cleared.

- Approached the individual piles at right angles to the sweeping direction so as to create a single heap.

- This heap is now ready for collection/scooping to your wasted container.

- OPERATE LEFT/RIGHT HAND SWEEP: If this option is chosen (normally for clearing single track roads/access routes) the following instructions need to be adhered to after step 1 above:

- Insert the sweep angle into the slot on the desired side of the stop plate.

- Insert the safety clip through the hole on the vertical pin over the sweep plate.

- Drive forks into fork hooks until the tip of one fork touches the stop plate and the other against the sweep angle, firstly ensuring that the twist screws are suitably retracted.

- Manual adjustment maybe required to truly align the unit.

- Once the forks are fully inserted tighten the twist screws onto the fork blade ensuring that they are fully tightened.

- The attachment is now ready for use.

Maintenance

- The Fork Mounted Brush should be inspected monthly for general condition with particular attention paid to: A – All weld points, B – Wear and distortion of fork hoops and twist screws, C – Any damaged/worn components, D – General condition of bristles

- Damage or failure must be reported and rectified immediately prior to re-use of the attachment.

- General surface rusting especially in the critical areas should be treated with proprietary inhibitors, primers and paint on a regular basis.

- To ensure even bristle wear swap the front and rear bristles back to front and visa vera.

Health And Safety

- The manager of the department or section where the attachment is to be used must be responsible for ensuring the operators are fully conversant with the attachment, its operation, maintenance and that the twist screws are fully tightened.

- We recommend that cornering is not under taken when sweeping as there will be spillage of material on the outside of the turn.

- Do not drive into the fork hoops without retracting the twist screws.

- Do not reverse with the brush in contact with the sweeping surface as the unit may become dislodged from the brush.

- When in storage do not stand or place items on the brush hood as damage could be incurred to the bristles and/or injury to personnel.